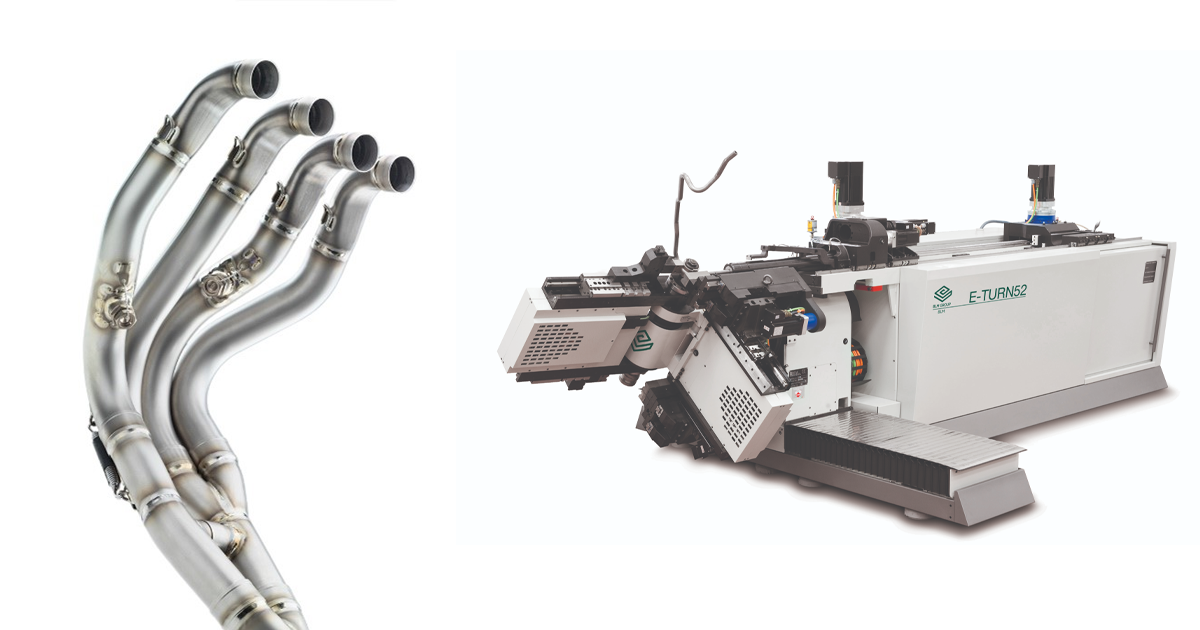

BLM GROUP will be demonstrating its E-TURN all-electric tube bender with in-process right and left hand bending that provides design freedom in the manufacture of tubular components. This multi-stack tube bender can perform, in one continuous cycle, right and left hand bends of either fixed or variable radius. The flexibility, accuracy and speed of the E-TURN makes it well suited for automotive, job shop and motorcycle applications.

The E-TURN52, displayed at the SEMA Show, has the ability to process tubes up to 2” in diameter. The all-electric drive ensures precision control of the 15-axes movements, providing consistency, high accuracy, perfect quality bends and zero scrap. Tubes in most materials and section types—such as round, square, rectangle, flat sided, oval and elliptical—can be automatically loaded, bent and unloaded.

A key differentiator of the E-TURN is the VGPNext programming and 3D simulation software. By simply inputting the component bend coordinates, the complete bending program is graphically simulated, highlighting potential collision risks and producing the optimal working cycle. Component feasibility is checked virtually, eliminating the need for prototype tooling or physical testing on the machine. Unloading of the finished component is also automatically managed by VPGNext, with the 180-degree head rotation allowing the component to be unloaded in the position required.

Changeover times are significantly reduced and machine-setup simplified as all the critical settings for the machine tooling are managed automatically by the CNC, including clamps, pressure die, mandrel position, retraction, center line radius, etc. Additionally, the self-calibration feature enables true simultaneous axis movement with automatic adjustment of these settings.

The all-electric technology of the E-TURN offers reduced power consumption, typically offering 80% savings as compared to conventional hydraulic bending machines. Maintenance is also reduced due to simplified cabling and components.

The E-TURN is available in four sizes capable of handling maximum tube O.D. capacity ranging from 30mm x 2mm (1.18-in. x 0.079-in.) up to 50.8mm x 1.5mm (2-in. x 0.059-in.). Depending on the system, the E-TURN offers a minimum bending radius of 25 – 35mm and a maximum bending radius of 150 to 165mm.

For more information, visit www.blmgroup.com/tube-benders/e-turn