The story of Crane Cams began in 1953 when Harvey J. Crane, Jr. set about grinding his first camshaft in the corner of his father’s machine shop in Hallandale, Florida. An apprentice machinist, young Harvey became interested in “souping-up” his flathead Ford V-8 hot rod. Like most others, he was strongly influenced by the various “hot rodding” magazines, ordering his first cam from a California cam company’s ad.

Today, Crane Cams has a significant amount of R&D and manufacturing resources to rely on, including an immense number of state-of-the-art CNC machining centers, dyno cells, Spintrons and a fully government-certified emissions lab. The company has the ability to produce fully digitized camshafts using Landis CNC equipment, as well as grinding cams via traditional methods using production masters. Quality control is assured through state-of-the-art Zeiss optical and Adcole equipment.

Gold Race® Roller Rocker Arms

Gold Race® Roller Rockers from Crane are some of the most rugged and accurate on the planet. They are constructed from durable aluminum to handle spring pressures of 700 lbs. (standard) or 900 lbs. (“wide body”). These rocker arms are manufactured using the latest in multi-axis CNC equipment and only one fixturing operation is employed. This eliminates the tolerance “stacking” that occurs when parts are made on multiple machines, whether they’re moved by men or robots.

Gold Race® Roller Rockers from Crane are some of the most rugged and accurate on the planet. They are constructed from durable aluminum to handle spring pressures of 700 lbs. (standard) or 900 lbs. (“wide body”). These rocker arms are manufactured using the latest in multi-axis CNC equipment and only one fixturing operation is employed. This eliminates the tolerance “stacking” that occurs when parts are made on multiple machines, whether they’re moved by men or robots.

Gold Race® Rockers also feature Crane’s exclusive Quick-Lift™ technology. This means the pushrod seat is positioned differently than other rocker arms, with the variance in arcs resulting in an accelerated opening and closing. For instance, a 1.7 ratio rocker will initially open the valves at a 1.78 net ratio, then converge to a nominal 1.7 ratio at approximately mid-lift. These accelerated opening and closing events provide increased horsepower and torque that can be easily measured. Crane Gold Race® Roller Rockers are the best stud-mount aluminum option from Crane Cams on the market today.

Energizer Retro-Fit Hydraulic Roller Lifters

Crane Cams has introduced the new Energizer Series of Retro-Fit Hydraulic Roller Lifters for high performance street engine applications.

Crane Cams has introduced the new Energizer Series of Retro-Fit Hydraulic Roller Lifters for high performance street engine applications.

You will now be able to convert your early model engine from a flat tappet design to the modern hydraulic roller valve train system; providing a reduction in friction, an increased RPM range with enhanced horsepower and torque. There is normally no machining required, these tie-bar design lifters are an easy “drop-in” conversion allowing you to take advantage of the modern hydraulic roller camshaft technology.

Your favorite high performance muscle car, custom Street Rod, or high torque towing vehicle can be moved into the 21st Century. The Energizer Series of lifters are offered for several popular engine applications, see the chart below.

Design Lobe Profiles for RaceMax™ Series for LS Chevrolet Engines

The new RaceMax™ Series (LSMP389 family) of lobes designed specifically for 2006–up Chevrolet V-8 LS3/L92 6.2L engines (but can be used in all LS and Gen. III/Gen. IV engines with three bolt timing sets.) These profiles are made for maximum race effort drag racing applications that include compatibility for Nitrous Oxide systems.

The new RaceMax™ Series (LSMP389 family) of lobes designed specifically for 2006–up Chevrolet V-8 LS3/L92 6.2L engines (but can be used in all LS and Gen. III/Gen. IV engines with three bolt timing sets.) These profiles are made for maximum race effort drag racing applications that include compatibility for Nitrous Oxide systems.

These profiles are serious—think dyno shootout rather than daily driver. These profiles are for “built engines” with internal modifications and upgrades, including ported heads and aftermarket pistons for additional valve clearance.

Naturally, the car will require a full exhaust system and dyno tuning. Aftermarket racing valve springs will be mandatory. These designs are for racing applications where valve train noise is not a consideration.

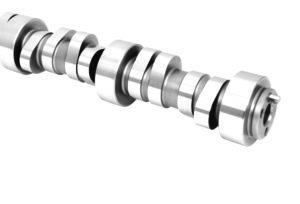

Custom Tool Steel Camshafts

Crane Cams tool steel camshafts are custom made to match any engine configuration. These cams can be built “one-off” to any linear spacing, journal size, firing order that you need.

Crane Cams tool steel camshafts are custom made to match any engine configuration. These cams can be built “one-off” to any linear spacing, journal size, firing order that you need.

This service meets the demand for the incredible variety of design combinations created by the cylinder head and block manufactures of today. These are the ultimate camshafts for high performance and all out racing applications. These new camshafts are made from a dedicated variety of tool steel using a through hardening heat treating process to create an extremely stable part that is resistant to surface wear, twist and deflection with the ability to withstand high surface loading and shock.

Finish ground camshafts can be ordered to your specifications either one at a time, or in quantity. Once the cam core is produced, it is rough ground, through hardened, then finish ground to best suit your application. If you can supply a print, a sample camshaft, or specify what modifications are needed to an existing product, Crane Cams can produce a camshaft to meet your requirements. For unique applications, the company maintains a proprietary relationship, making the camshaft exclusive to the customer.

Popular applications, such as Chrysler 426 Hemi and Johnson/Rodeck 481X cores are maintained in stock.

Custom Options:

- Cam bearing journal diameters

- Nose configurations (bolt holes, dowel pins/keyways, integral gear drive flanges)

- Linear spacing and widths of journals and lobes, cam barrel diameters

- Lobe angular placement for different lifter bank angle blocks

- Firing orders

- Gun drilling

- Distributor/oil pump drive gears hobbed on camshaft, fuel pump eccentrics

- Rear drive configurations

- Oil passages

- Micro polishing

For more information, visit www.cranecams.com